Best CK 45 Carbon Steel Manufacturers & Suppliers in Mumbai – High Quality Carbon Steel Round Supply

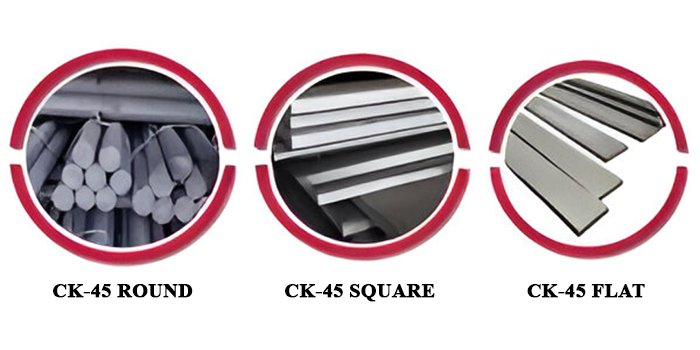

Looking for trusted CK 45 Carbon Steel Round Bar Manufacturers & Suppliers in Mumbai ? We Titan Steel, Mumbai provide durable, precision-engineered carbon steel round bars for construction, industrial, and engineering needs. Get reliable quality, competitive prices, and timely delivery from leading suppliers in Mumbai.

CK-45 Grade Overview:

CK-45 is a medium-carbon steel that excels in manufacturing parts subject to higher loads and complex forms, such as vehicle and machine components (e.g., ship shafts, transmission parts, and wheel hubs). It performs well at low temperatures (down to -25°C) and exhibits favorable creep behavior up to 480°C, making it suitable for heavy-duty applications.

CK-45 Grade Applications:

- Cutting tools with high wear and impact resistance

- Punching dies, screw dies, and complex-shaped punches

- Forging dies for the forging industry

- Tools for the screw industry, such as heading forming molds and teeth punches

CK-45 Equivalent Grades:

| Country | Equivalent Standards |

|---|---|

| USA | ASTM A681 (1045) |

| Germany | DIN 17350 (CK45) |

| Japan | JIS G4403 (S45C) |

| China | GB/T 1299 (45) |

| ISO | ISO 4957 (C45E4) |

Additional Comparable Grades:

Similar materials include EN8, EN9, EN24, EN31, 42CrMo4, SAE 1018, SAE 4140, and many other alloy steels.

CK-45 Chemical Composition:

| Element | C | Si | Mn | P (max) | S (max) |

|---|---|---|---|---|---|

| % | 0.42-0.50 | 0.40 | 0.50-0.80 | 0.04 | 0.03 |

CK-45 Mechanical Properties:

- Elastic Modulus: 217 GPa at -100°C

- Elongation: 4-8% at 20°C

- Poisson’s Ratio: 0.29 at 20°C

- Shear Modulus: 75-80 GPa at 20°C

- Tensile Strength: 580-770 MPa at 20°C

- Yield Strength: 330-640 MPa at 20°C

CK-45 Hardness:

The hardness, measured in Rockwell C, is 201-269 HB, achieved through water quenching at 820-870°C for 5 minutes.

CK-45 Heat Treatment:

The heat treatment process involves furnace cooling at 28ºC per hour to 650ºC, followed by air cooling. Hardening is done by heating to 800-845ºC and quenching in oil or water.

CK-45 Hardening:

To harden CK-45, heat it to an austenitizing temperature of 800-845ºC, followed by oil or water quenching. Flame or induction hardening can also be applied, followed by tempering to relieve stress.

CK-45 Tempering:

Tempering should be done at 552°C, achieving a hardness of 201-269 HB after tempering.

CK-45 Physical Properties:

| Property | Value | Unit |

|---|---|---|

| Thermal Expansion | 10 e-6/K | |

| Thermal Conductivity | 25 W/m·K | |

| Specific Heat | 460 J/kg·K | |

| Melting Temperature | 1450-1510°C | |

| Density | 7.8 g/cm³ | at 20°C |

| Electrical Resistivity | 0.55 Ohm·mm²/m |

CK-45 Thermal Properties:

- Thermal Expansion Coefficient: 1.08E-5 1/K at -100°C

- Thermal Conductivity: 41.7 W/m·K at 20°C

- Thermal Diffusivity: 11.6 mm²/s at 20°C

CK-45 Forging Properties:

Preheat to 552°C, followed by heating to 820-870°C for forging. Forging should not occur below 560°C. After forging, allow the material to cool slowly.

CK-45 Stress Relieving:

Stress relieving is essential when machining or working with cold materials.

CK-45 Normalizing:

Normalize the material by heating it to 840-870°C and allowing it to air cool.

CK-45 Annealing:

Small CK-45 forgings can be annealed by heating them to 790-870°C, followed by furnace cooling at 28ºC per hour to 650ºC, and then air cooling.

CK-45 Density:

The density of CK-45 is 7.8 g/cm³ at 20°C.

CK-45 Machinability:

The machinability of CK-45 is rated at 80% compared to AISI 1112 steel, known for its high machinability.

CK-45 Welding:

Welding of CK-45 requires pre-heating and post-weld heat treatment to avoid cracking and ensure good weld quality.

Titan Steel & Engineers Related Products:

Carbon Steel, Alloy Steel, Bright Steel, Spring Steel, Die Steel & Tool Steel, Special Alloy Steel

For Visit us Maps

Supply Cities

- Mumbai

- Ahmedabad

- Amaravathi

- Ambattur

- Bangalore

- Belgaum

- Chennai

- Chittoor

- Coimbatore

- Dindigul

- Mysore

- Nellore

- Hyderabad

- Kochi

- Mangalore

- Tirupur

- Tuticorin

- Madurai

- Andhra Pradesh

- Karnataka

- Puducherry

- Kerala

- Tamil Nadu

- Telangana

- Visakhapatnam

- Kochi

- Kerala

- Hubli-Dharwad

- Karnataka

People also search as:

CK45 Steel Round Bar, CK45 Steel Round Bar Manufacturers, CK45 Steel Suppliers, CK45 Stockist, CK45 Steel Dealers, CK45 Steel Distributors, CK45 Wholesalers, CK45 Steel Traders, CK45 Steel Square Distributors, CK45 Steel Flat Bar, CK45 Steel Companies Near me.

CK45, CK45 Steel, CK45 Chemical composition, CK45 Mechanical properties, CK45 Equivalent Grades, CK45 Steel plate, CK45 Steel sheet, CK45 Manufacturers, CK45 Suppliers, CK45 Dealers, CK45 Stockist, CK45 Distributors, CK45 Wholesalers, CK45 Traders.