Best M2 Die Steel & Tool Steel Manufacturers in Mumbai – Premium Quality Suppliers

Looking for reliable Best M2 Die Steel & Tool Steel Manufacturers in Mumbai? We Titan Steel offer high-grade, durable, and wear-resistant steels for moulds, dies, cutting tools, and industrial applications. Get precision, strength, and timely delivery from trusted suppliers in Mumbai.

M2 Grade Overview:

M2 is a molybdenum high-speed tool steel and is part of the Group M steels as per the AISI classification system. These steels are highly popular in the US, with over 95% of high-speed steels manufactured falling under this category. M2 steel offers excellent toughness and is favored for its superior cutting performance compared to tungsten high-speed steels. Moreover, M2 steel is more cost-effective, making it widely used in various cutting applications. It can also be coated with titanium nitride, titanium carbide, and other coatings through physical vapor deposition to enhance tool performance and longevity.

Applications of M2 Steel:

M2 high-speed tool steel is commonly used for manufacturing cutting tools due to its high wear resistance. Typical applications include:

- Twist drills

- Reamers

- Broaching tools

- Taps

- Milling tools

- Metal saws

- Plastic molds requiring elevated wear resistance

- Cold-forming tools like extrusion rams and dies M2 is also used for punches, die applications, and screws.

Equivalent Grades of M2 Steel:

| Country | USA | Germany | Japan |

|---|---|---|---|

| Standard | ASTM A600 | DIN EN ISO 4957 | JIS G4403 |

| Grades | M2 | 1.3343 | SKH51 |

Chemical Composition of M2 Steel:

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.78 – 1.05 |

| Silicon (Si) | 0.20 – 0.45 |

| Manganese (Mn) | 0.15 – 0.40 |

| Phosphorus (P) | Max 0.03 |

| Sulfur (S) | Max 0.03 |

| Chromium (Cr) | 3.75 – 4.5 |

| Molybdenum (Mo) | 4.5 – 5.5 |

| Nickel (Ni) | 0.3 |

| Vanadium (V) | 1.75 – 2.2 |

| Copper (Cu) | 0.25 |

| Tungsten (W) | 5.50 – 6.75 |

Mechanical Properties of M2 Steel:

| Property | Metric | Imperial |

|---|---|---|

| Hardness, Rockwell C (tempered at 1150°F, quenched at 2200°F) | 62 | 62 |

| Hardness, Rockwell C (as-hardened, quenched at 2200°F) | 65 | 65 |

| Compressive yield strength (tempered at 300°F) | 3250 MPa | 471000 psi |

| Izod impact unnotched (tempered at 300°F) | 67 J | 49.4 ft-lb |

| Abrasion loss (as-hardened, ASTM G65) | 25.8 mm³ | 25.8 mm³ |

| Abrasion loss (tempered at 1275°F, ASTM G65) | 77.7 mm³ | 77.7 mm³ |

| Poisson’s ratio | 0.27 – 0.30 | 0.27 – 0.30 |

| Elastic modulus | 190 – 210 GPa | 27557 – 30458 ksi |

Hardness of M2 Steel:

M2 steel has a typical hardness of 62-65 HRC, making it suitable for high-performance cutting applications.

Heat Treatment of M2 Steel:

- Pre-heating: M2 is preheated in two steps: first at 450 – 500°C, and then at 850 – 900°C.

- Hardening: The final hardening temperature is 1200 – 1250°C. It is important not to leave the steel at the hardening temperature for too long.

- Quenching: The steel is quenched in warm oil or brine to about 500°C, followed by air cooling to room temperature.

Tempering of M2 Steel:

M2 should be tempered by heating it to the desired temperature and holding it for at least two hours (or one hour per 25 mm of thickness). Double tempering is recommended for optimal performance.

| Tempering Temperature (°C) | Resulting Hardness (HRC) |

|---|---|

| 500°C | 64 HRC |

| 550°C | 65 HRC |

| 600°C | 64 HRC |

| 650°C | 61 HRC |

Physical Properties of M2 Steel:

| Property | Metric | Imperial |

|---|---|---|

| Density | 8.16 g/cm³ | 0.294 lb/in³ |

| Melting point | 4680°C | 2600°F |

Thermal Properties of M2 Steel:

| Property | Metric | Imperial |

|---|---|---|

| Coefficient of thermal expansion (CTE) (@20–100°C) | 10 μm/m°C | 5.56 μin/in°F |

| Coefficient of thermal expansion (CTE) (@20–500°C) | 12.2 μm/m°C | 6.78 μin/in°F |

| Coefficient of thermal expansion (CTE) (@20–850°C) | 12.6 μm/m°C | 7 μin/in°F |

Forging Properties of M2 Steel:

M2 steel should be preheated slowly and uniformly to 850-900°C. The forging temperature should then be raised to 1050-1150°C. If the temperature drops below 880-900°C during forging, reheating is necessary. After forging, cool the steel component very slowly.

Stress Relieving of M2 Steel:

M2 components should be stress-relieved after machining or grinding and before hardening. Heat the component to 600-700°C and soak for approximately two hours, then cool in air.

Annealing of M2 Steel:

M2 steel is annealed at 1204°C (2200°F) and cooled at a rate of 72°C (162°F) per hour or slower to achieve optimal results.

Machinability of M2 Steel:

M2 tool steel can be shaped by grinding. However, its machinability is only about 50% compared to water-hardening tool steels, making it relatively challenging to machine.

Welding of M2 Steel:

When welding M2 steel, it is important to preheat the part to 1100°F (600°C) and maintain this temperature during welding. Allow the parts to cool slowly to avoid distortion and cracking.

This steel is widely appreciated for its toughness, wear resistance, and ability to retain hardness at high temperatures. M2 is used extensively in high-speed cutting tools and applications requiring durability and precision.

Titan Steel & Engineers Related Products:

Carbon Steel, Alloy Steel, Bright Steel, Spring Steel, Die Steel & Tool Steel, Special Alloy Steel

For Visit us Maps

Supply Cities

- Mumbai

- Ahmedabad

- Amaravathi

- Ambattur

- Bangalore

- Belgaum

- Chennai

- Chittoor

- Coimbatore

- Dindigul

- Mysore

- Nellore

- Hyderabad

- Kochi

- Mangalore

- Tirupur

- Tuticorin

- Madurai

- Andhra Pradesh

- Karnataka

- Puducherry

- Kerala

- Tamil Nadu

- Telangana

- Visakhapatnam

- Kochi

- Kerala

- Hubli-Dharwad

- Karnataka

People also search as:

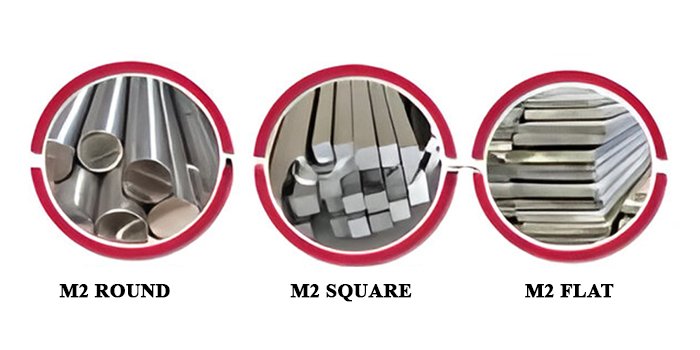

M2 Steel Round Bar, M2 Steel Round Bar Manufacturers, M2 Steel Suppliers, M2 Stockist, M2 Steel Dealers, M2 Steel Distributors, M2 Wholesalers, M2 Steel Traders, M2 Steel Square Distributors, M2 Steel Flat Bar, M2 Steel Companies Near me.

M2, M2 Steel, M2 Chemical composition, M2 Mechanical properties, M2 Equivalent Grades, M2 Steel plate, M2 Steel sheet, M2 Manufacturers, M2 Suppliers, M2 Dealers, M2 Stockist, M2 Distributors, M2 Wholesalers, M2 Traders.