Best P-20 Ni Die Steel & Tool Steel Manufacturers in Mumbai – Premium Quality Suppliers

Looking for reliable Best P-20 Ni Die Steel & Tool Steel Manufacturers in Mumbai? We Titan Steel offer high-grade, durable, and wear-resistant steels for moulds, dies, cutting tools, and industrial applications. Get precision, strength, and timely delivery from trusted suppliers in Mumbai.

P-20+Ni Grade Introduction:

P-20+Ni (DIN 1.2738) is a plastic mold steel commonly used for large molds requiring enhanced hardness and toughness. The addition of nickel to the steel increases its toughness, while chromium and molybdenum contribute to wear resistance and hardness. Pre-hardened to 280-320 HB, it is known for good machinability and polishability, particularly in large molds and tooling applications. This steel is often used in the plastic mold industry, hydroforming tools, and die-casting dies.

P-20+Ni Grade Applications:

P-20+Ni is primarily used in low-temperature applications that require durability and resistance to wear. Common uses include:

- Plastic mold dies (especially for large molds)

- Injection molds

- Hydroforming tools

- Die-casting dies

P-20+Ni Equivalent Grades:

- Germany (DIN): 1.2738

- USA (ASTM/AISI): P20+Ni

Additional Grades:

Alongside P-20+Ni, the following related grades are also supplied:

- MS, EN8, EN9, EN24, EN31

- P20, P20+S, 42CrMo4

- SAE1010, SAE8620, 16MNCR5

- C45, C55MN75, SCM420

P-20+Ni Chemical Composition:

The chemical composition of P-20+Ni is as follows:

| Element | Percentage (DIN 1.2738) | Percentage (ASTM P20+Ni) |

|---|---|---|

| Carbon (C) | 0.35-0.45% | 0.28-0.40% |

| Manganese (Mn) | 1.30-1.60% | 0.60-1.00% |

| Phosphorus (P) | ≤ 0.03% | ≤ 0.03% |

| Sulfur (S) | ≤ 0.03% | ≤ 0.03% |

| Silicon (Si) | 0.20-0.40% | 0.20-0.80% |

| Chromium (Cr) | 1.80-2.10% | 1.40-2.00% |

| Molybdenum (Mo) | 0.15-0.25% | 0.30-0.55% |

| Nickel (Ni) | 0.90-1.20% | 0.90-1.20% |

P-20+Ni Mechanical Properties:

- Tensile Strength: 1100 MPa (at 20°C)

- Yield Strength: 980 MPa (at 20°C)

- Elongation: 13% (at 20°C)

- Section Shrinkage: 49% (at 20°C)

- Impact Toughness: ≥ 20J/cm² (at 20°C)

- Hardness (Pre-hardened): 235 HB

P-20+Ni Hardness:

The hardness of P-20+Ni is typically 235 HB when pre-hardened.

P-20+Ni Heat Treatment:

Typically delivered in pre-toughened condition, heat treatment may not be necessary unless specific hardness or wear resistance is required. For hardening:

- Hardening temperature: 840-870°C followed by quenching (oil, hot bath, or air).

- Post-hardening hardness: Up to 52 HRC.

P-20+Ni Tempering:

After hardening, tempering is recommended:

- Tempering temperature: Applied immediately after hardening.

- Duration: Minimum 1 hour for each 20 mm thickness of the part.

- Recommended: Double tempering for improved stability.

P-20+Ni Physical Properties:

- Density: 7.80 g/cm³

- Modulus of Elasticity: 205 GPa

- Thermal Conductivity: 29.0 W/m.K (at 100°C: 33.5 W/m.K)

- Specific Heat Capacity: 0.46 J/g.K

P-20+Ni Thermal Properties:

P-20+Ni steel has good thermal conductivity, which is advantageous in mold-making applications where temperature management is critical.

P-20+Ni Forging Properties:

- Hot forming temperature: 1093-898°C

P-20+Ni Stress Relieving:

Stress relieving is carried out at approximately 650°C to reduce internal stresses from machining and other processing.

P-20+Ni Normalizing:

Normalizing is done at 900°C to refine the grain structure and improve toughness.

P-20+Ni Annealing:

- Annealing temperature: 710-740°C for 2 to 5 hours.

- Cooling: Slow cooling at 10-20°C per hour down to approximately 600°C, followed by air cooling. This process achieves a maximum Brinell hardness of 235 HB.

P-20+Ni Machinability:

P-20+Ni has excellent machinability, rated at around 80% of water-hardening steels. This makes it suitable for detailed mold machining operations.

P-20+Ni Welding:

P-20+Ni can be welded using conventional methods. Preheating and post-weld heat treatment are recommended to prevent cracking and ensure the integrity of the welded area.

This grade is a reliable choice for large plastic molds and tooling applications due to its excellent machinability, polishability, and toughness.

Titan Steel & Engineers Related Products:

Carbon Steel, Alloy Steel, Bright Steel, Spring Steel, Die Steel & Tool Steel, Special Alloy Steel

For Visit us Maps

Supply Cities

- Mumbai

- Ahmedabad

- Amaravathi

- Ambattur

- Bangalore

- Belgaum

- Chennai

- Chittoor

- Coimbatore

- Dindigul

- Mysore

- Nellore

- Hyderabad

- Kochi

- Mangalore

- Tirupur

- Tuticorin

- Madurai

- Andhra Pradesh

- Karnataka

- Puducherry

- Kerala

- Tamil Nadu

- Telangana

- Visakhapatnam

- Kochi

- Kerala

- Hubli-Dharwad

- Karnataka

People also search as:

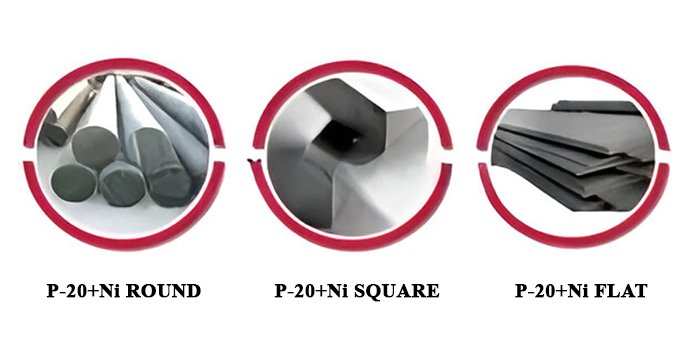

P-20+Ni Steel Round Bar, P-20+Ni Steel Round Bar Manufacturers, P-20+Ni Steel Suppliers, P-20+Ni Stockist, P-20+Ni Steel Dealers, P-20+Ni Steel Distributors, P-20+Ni Wholesalers, P-20+Ni Steel Traders, P-20+Ni Steel Square Distributors, P-20+Ni Steel Flat Bar, P-20+Ni Steel Companies Near me.

P-20+Ni, P-20+Ni Steel, P-20+Ni Chemical composition, P-20+Ni Mechanical properties, P-20+Ni Equivalent Grades, P-20+Ni Steel plate, P-20+Ni Steel sheet, P-20+Ni Manufacturers, P-20+Ni Suppliers, P-20+Ni Dealers, P-20+Ni Stockist, P-20+Ni Distributors, P-20+Ni Wholesalers, P-20+Ni Traders.