Great Experience in Steel

we are manufacturer in steel

It is a long established fact that a reader will be distracted the readable content of a page when looking at layout the point of using

About Our Company

Titan Steel & Engineers

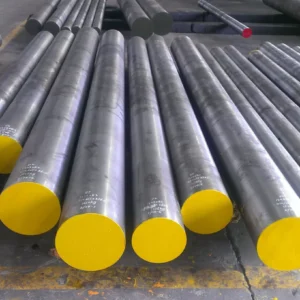

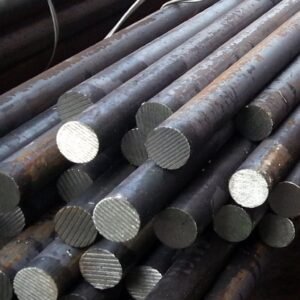

Titan Steel & Engineers is a leading provider of high-quality carbon steel, alloy steel, tool steel, die steel, and a range of other specialized materials. Serving industries across India, our product portfolio includes round bars, flat bars, square bars, and customized shapes tailored to meet the precise specifications of our clients. With locations strategically positioned in Mumbai, Pune, Uttar Pradesh (Gonda), we ensure that our products are always within reach, delivering strength and reliability across multiple sectors.

Our story began with a vision—to revolutionize the steel industry with a focus on quality, precision, and trust. From a modest workshop in Mumbai, Titan Steel & Engineers was founded by a group of visionary entrepreneurs who were driven by a shared passion for metallurgy and a determination to make their mark. In those early days, the challenges were immense—limited resources, countless obstacles, and an industry dominated by established players. But we pressed on, fueled by the belief that the key to success lay in unwavering quality and customer satisfaction.

Our Categories

Our Gallery

Get in touch!

talk to us

Steel Manufacturer and Supplier in Mumbai

Titan Steel & Engineers is a leading provider of high-quality carbon steel, alloy steel, tool steel, die steel, and a range of other specialized materials.

call emergency

+91 738 586 3226

hubofsteel.com is proudly powered by WordPress