Best EN47 Spring Steel Round Bar Manufacturers in Mumbai | Quality Steel Suppliers

Looking for reliable best EN47 Spring Steel Round Bar Manufacturers in Mumbai? Titan Steel supply high-tensile, durable spring steel round bars ideal for automotive, construction, and industrial applications. Get precision-engineered bars with superior performance, competitive pricing, and timely delivery from trusted manufacturers in Mumbai.

EN47 Grade Introduction:

EN47 Spring Steel, also known as 51CrV4, 50CrV4, DIN 1.8159, or AISI 6150 in various international standards, is supplied in rolled condition. This alloy is ideal for oil hardening and tempering. When processed in this manner, EN47 exhibits superior spring characteristics combined with excellent wear and abrasion resistance. Hardened EN47 steel offers remarkable toughness and shock resistance, making it an excellent choice for applications exposed to stress, shock, and vibration.

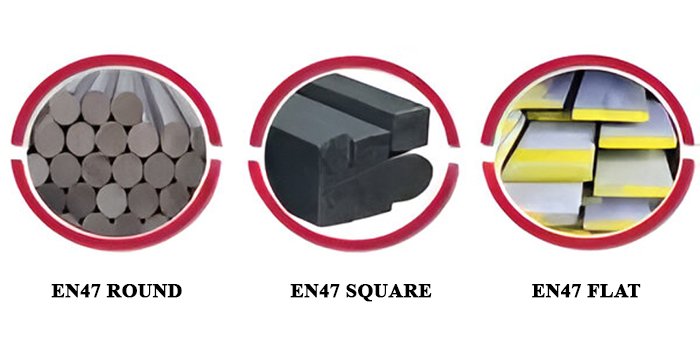

Our product range now includes EN47 Spring Steel Round Bars. This steel is commonly used in applications such as tractors, heavy vehicles, and industrial production load-bearing components. It is particularly suitable for larger plate springs and helical springs, and is widely utilized in general engineering applications. Hardened EN47 delivers exceptional shock resistance and toughness, making it ideal for components subjected to significant stress and vibration.

EN47 Grade Application

EN47 Spring Steel is extensively used in the motor vehicle industry and a variety of general engineering applications. It is particularly suited for components requiring high tensile strength and toughness. Typical applications include crankshafts, steering knuckles, gears, spindles, and pumps.

EN47 Equivalent Grades

- BS970: 735A50, 735A51

- DIN: 1.8159

- AISI: 6150

- ISO: 50CrV4, 50CV4

- ASTM: A829

Additional Grades:

MS, EN1A, EN3B, EN8, EN8D, EN9, EN24, EN31, EN32B, EN36C, EN41B, EN43B, EN47, EN353, IS2062, 42CrMo4, HCHCR, D2, D3, H-11, H-13, CW-1, OHNS, M2, M35, M42, DIN 1.2714, P20, P20+S, P20+Ni, SCM420, ASTM A36, ASTM A105, SAE1018, SAE1010, SAE4140, SAE8620, 16MNCR5, 20MNCR5, C20, C45, C50, C60, CK45, 20C8, 40C8, 45C8, 55C8, C55MN75, SAE52100, S40C, S355J2G3.

Our Supply Range

- Price List: EN24

EN47 Chemical Composition

| Element | C (%) | Mn (%) | Si (%) | P (%) | Cr (%) | S (%) | V (%) | Ni (%) |

|---|---|---|---|---|---|---|---|---|

| Content | 0.45-0.55 | 0.50-0.80 | 0.50 | 0.06 | 0.80-1.20 | 0.06 | 0.15 | – |

EN47 Mechanical Properties

- Hardening Temperature: 840-870°C

- Quenching Medium: Oil

- Tempering Temperature: 150-200°C

EN47 Heat Treatment

Heat treatment parameters, including heating rates, cooling, and soaking times, will vary based on factors like component shape, size, furnace type, and quenching medium. For detailed guidance, consult your heat treatment provider.

Hardening: Heat slowly to 650-700°C, soak thoroughly, then heat to 830-860°C. Quench in oil.

Tempering: Temper immediately after quenching while still warm. Reheat to the tempering temperature and soak for one hour per 25 mm of thickness (minimum 2 hours). Cool in air. Typical tempering temperatures range from 400-600°C.

EN47 Hardness

- Brinell Hardness: 150-200

- Rockwell Hardness: Equivalent range not specified; consult specific standards or testing.

EN47 Physical Properties

- Density: 8.08 g/cm³ (0.292 lb/in³)

- Melting Point: 1425°C (2600°F)

EN47 Thermal Properties

Information on specific thermal properties not provided; consult detailed specifications for precise data.

EN47 Forging Properties

Preheat carefully, then raise to 1050°C for forging. Avoid forging below 840°C. After forging, cool slowly, preferably in a furnace.

EN47 Stress Relieving

Information not provided; typically involves heating to a lower temperature to relieve internal stresses.

EN47 Normalizing

Details not provided; usually involves heating to a specific temperature to achieve uniform properties.

EN47 Annealing

Heat slowly to 820-840°C, soak well, and cool slowly in the furnace.

EN47 Machinability

Information on machinability not provided; consult specific guides or manufacturers for machining details.

EN47 Welding

For welding EN47 chrome vanadium spring steel, consult your welding consumables supplier for comprehensive assistance and recommendations.

Titan Steel & Engineers Related Products:

Carbon Steel, Alloy Steel, Bright Steel, Spring Steel, Die Steel & Tool Steel, Special Alloy Steel

For Visit us Maps

Supply Cities

- Mumbai

- Ahmedabad

- Amaravathi

- Ambattur

- Bangalore

- Belgaum

- Chennai

- Chittoor

- Coimbatore

- Dindigul

- Mysore

- Nellore

- Hyderabad

- Kochi

- Mangalore

- Tirupur

- Tuticorin

- Madurai

- Andhra Pradesh

- Karnataka

- Puducherry

- Kerala

- Tamil Nadu

- Telangana

- Visakhapatnam

- Kochi

- Kerala

- Hubli-Dharwad

- Karnataka