Description

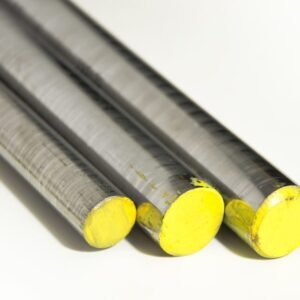

s6 Tool Steel

Upgrade your industrial applications with s6 Tool Steel, the dependable choice for exceptional toughness and durability. Designed to perform under demanding conditions, this versatile steel ensures reliability and strength, making it an invaluable resource for a wide range of industries.

Key Features and Specifications

- Superior Toughness: Built to withstand heavy impact, s6 Tool Steel offers unmatched resilience even in extreme environments.

- High Hardness Levels: Provides excellent wear resistance to ensure a longer lifespan for your tools and components.

- Chromium Content: Enhanced corrosion resistance protects against environmental wear and tear, reducing maintenance needs.

- Heat and Shock Resistance: Engineered to maintain integrity under thermal and mechanical shocks without compromising performance.

Applications and Use Cases

s6 Tool Steel is ideal for industries requiring high-performance tooling materials. Its applications include cold-work tooling, die blocks, punches, and components for heavy-duty machinery. Additionally, it’s a go-to material for applications where impact resistance and durability take precedence.

Certifications and Standards

Backed by a commitment to quality, s6 Tool Steel conforms to industry standards and certifications, ensuring it meets stringent requirements for safety and performance in industrial applications.

Discover how s6 Tool Steel can meet your business needs and elevate your projects. [Contact Us Today] to learn more an

Supply Cities:

Mumbai Ahmedabad, Amaravathi, Ambattur, Bangalore, Belgaum, Chennai, Chittoor, Coimbatore, Dindigul, Mysore, Nellore, Hyderabad, Kochi, Mangalore, Tirupur, Tuticorin, Madurai, Andhra Pradesh, Karnataka, Puducherry, Kerala, Tamil Nadu, Telangana, Visakhapatnam, Kochi, Kerala, Hubli-Dharwad, Karnataka, Ghaziabad Kolkata.