Description

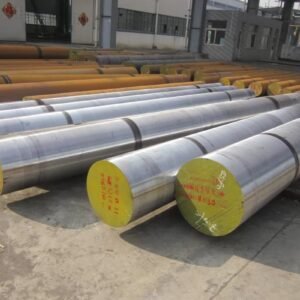

SAE 52100 Grade Introduction:

SAE 52100 is a high-quality alloy bearing steel, belonging to the category of high-carbon chromium-containing low alloy steels. This steel grade is commonly oil quenched and tempered, resulting in a hardness range of 28-34 HRC. When annealed, SAE 52100 delivers a hardness of less than 250HB. It is equivalent to DIN 100Cr6 and GB GCr15 steels, and these can often be used interchangeably for similar applications.

SAE 52100 Grade Applications:

SAE 52100 steel is primarily used in bearing applications in rotating machinery. It finds widespread use in valve bodies, pumps, fittings, high-load wheel applications, bolts, gears, and internal combustion engine components. Other common uses include electric locomotives, machine tools, tractors, steel rolling equipment, railway vehicles, and mining machinery components like shafts, rollers, and sleeves.

SAE 52100 Equivalent Grades:

| Country | Standard | Grades |

|---|---|---|

| USA | ASTM A295 | 52100 |

| German | DIN 17230 | 100Cr6/1.3505 |

| Japan | JIS G4805 | SUJ2 |

| British | BS 970 | 535A99/EN31 |

Additional Steel Grades:

MS, EN1A, EN8, EN9, EN24, EN31, 42CrMo4, H13, D2, M42, and others.

SAE 52100 Chemical Composition:

| Standard | Grade | C | Mn | P | S | Si | Ni | Cr | Cu | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| ASTM A295 | 52100 | 0.93-1.05 | 0.25-0.45 | ≤0.025 | ≤0.015 | 0.15-0.35 | 0.25 | 1.35-1.60 | 0.30 | 0.10 |

SAE 52100 Mechanical Properties:

| Property | Value | Unit |

|---|---|---|

| Young’s Modulus | 200,000 | MPa |

| Tensile Strength | 50-880 | MPa |

| Elongation | 8-25 | % |

| Fatigue Strength | 275 | MPa |

| Yield Strength | 350 | MPa |

SAE 52100 Hardness:

- Brinell: Varies with quenching and tempering conditions

- Rockwell C: 62-66 depending on quenching in oil or water

- Vickers: 848-875 (converted from Rockwell C)

SAE 52100 Heat Treatment Properties:

The steel is typically heated at 816°C and quenched in oil. It may undergo normalizing at 872°C, followed by slow cooling to relieve machining stress.

SAE 52100 Hardening:

SAE 52100 can be hardened by cold working or through a heating and quenching process. It can be carburized at 913°C, followed by quenching, and then reheated at 788°C for a second quenching.

SAE 52100 Tempering:

After water or oil quenching, tempering is done to achieve the desired hardness as indicated by tempering curves.

SAE 52100 Physical Properties:

| Property | Metric | Imperial |

|---|---|---|

| Density | 7.81 g/cm³ | 0.282 lb/in³ |

| Melting Point | 1424°C | 2595°F |

SAE 52100 Thermal Properties:

| Property | Metric | Imperial |

|---|---|---|

| Thermal Expansion Coefficient | 11.9 µm/m°C | 6.61 µin/in°F |

| Thermal Conductivity | 46.6 W/mK | 323 BTU in/hr.ft².°F |

SAE 52100 Forging Properties:

The steel is forged between 927-1205°C, with post-forge equalization recommended at 745°C for 4-6 hours followed by air cooling.

SAE 52100 Stress Relieving:

Heat to 600-700°C, hold, and cool in the furnace. This helps relieve work hardening and residual stress.

SAE 52100 Normalizing:

The steel is normalized by heating to 930-950°C and air cooling, resulting in hardness between 302-388HBS.

SAE 52100 Annealing:

The alloy is annealed at 872°C followed by slow cooling to relieve machining or cold working stress.

SAE 52100 Density:

- Density: 7.81 g/cm³ (0.282 lb/in³)

SAE 52100 Machinability:

This steel can be machined using conventional techniques. Machinability is improved by performing sherardizing annealing at 649°C before machining.

SAE 52100 Welding:

Due to its high carbon content, welding is not typically recommended for SAE 52100 as it is mainly used for bearing applications. Welding could lead to potential issues such as cracking.

Supply Cities:

Mumbai Ahmedabad, Amaravathi, Ambattur, Bangalore, Belgaum, Chennai, Chittoor, Coimbatore, Dindigul, Mysore, Nellore, Hyderabad, Kochi, Mangalore, Tirupur, Tuticorin, Madurai, Andhra Pradesh, Karnataka, Puducherry, Kerala, Tamil Nadu, Telangana, Visakhapatnam, Kochi, Kerala, Hubli-Dharwad, Karnataka, Ghaziabad Kolkata.

People also search as:

SAE52100 Steel Round Bar, SAE52100 Steel Round Bar Manufacturers, SAE52100 Steel Suppliers, SAE52100 Stockist, SAE52100 Steel Dealers, SAE52100 Steel Distributors, SAE52100 Wholesalers, SAE52100 Steel Traders, SAE52100 Steel Square Distributors, SAE52100 Steel Flat Bar, SAE52100 Steel Companies Near me.

SAE52100, SAE52100 Steel, SAE52100 Chemical composition, SAE52100 Mechanical properties, SAE52100 Equivalent Grades, SAE52100 Steel plate, SAE52100 Steel sheet, SAE52100 Manufacturers, SAE52100 Suppliers, SAE52100 Dealers, SAE52100 Stockist, SAE52100 Distributors, SAE52100 Wholesalers, SAE52100 Traders.