Description

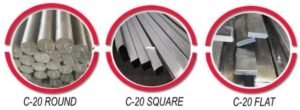

C20 Grade Introduction:

C20 carbon steel is a low carbon, mild steel grade typically available in hot rolled or bright drawn finish. As a low carbon steel, it offers good machinability, weldability, and low tensile strength. It is ideal for applications requiring moderate strength without the need for heat treatment. C20 can be welded easily and is commonly used in general engineering and fabrication purposes.

C20 Grade Application:

C20 steel is commonly used in general engineering and construction applications such as:

- Bolts

- Shafts

- Spacers

- Hubs

- Base plates

- Brackets

- Fixtures

- Jigs

C20 Equivalent Grades:

| Standard | Equivalent Grades |

|---|---|

| BS 970:1955 | 070M20 |

| British Standards | EN3A, EN32 |

| European | C15, C20 |

| Werkstoff | 1.0402, 1.0401, 1.1151 |

| SAE/AISI | 1020, 1023 |

Additional Grades Available:

In addition to C20, we also supply grades like MS, EN1A, EN8, EN24, and alloy steels such as 42CrMo4, H13, D2, and more.

C20 Chemical Composition:

| Element | C | Mn | Si | S (Max) | P (Max) |

|---|---|---|---|---|---|

| Content % | 0.17-0.23 | 0.30-0.60 | 0.10-0.40 | ≤0.045 | ≤0.045 |

C20 Mechanical Properties:

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 425 MPa | 61,600 psi |

| Yield Strength | 360 MPa | 52,200 psi |

| Shear Modulus | 80.0 GPa | 11,600 ksi |

| Bulk Modulus | 140 GPa | 20,300 ksi |

| Elastic Modulus | 190-210 GPa | 27,557-30,458 ksi |

| Poisson’s Ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at Break | 0.15 | 0.15 |

| Reduction of Area | 0.4 | 0.4 |

| Brinell Hardness | 121 | 121 |

| Knoop Hardness | 140 | 140 |

| Rockwell B Hardness | 68 | 68 |

| Vickers Hardness | 126 | 126 |

| Machinability Rating | 65 | 65 |

C20 Hardness:

The typical hardness of C20 steel is 121 HB, making it suitable for general-purpose machining and applications requiring moderate hardness.

C20 Heat Treatment:

Heat treatment varies based on the shape and size of the component. C20 steel is not ideal for heat treatment like higher carbon steels (e.g., EN8 or EN9), but if necessary, heat to 880-910°C, quench in water, and temper accordingly.

C20 Hardening:

For hardening, heat to 880-910°C, quench in water, and temper. This is typically only done if enhanced hardness is required.

C20 Tempering:

C20 can be tempered to adjust hardness and improve toughness, though it is typically not subjected to heavy heat treatments.

C20 Physical Properties:

| Property | Metric | Imperial |

|---|---|---|

| Annealed Hardness | HBS 156 max | HBS 156 max |

| Tensile Strength | ≥ 400 MPa | ≥ 58,000 psi |

| Yield Strength | ≥ 270 MPa | ≥ 39,000 psi |

| Elongation | ≥ 27% | ≥ 27% |

C20 Thermal Properties:

| Property | Metric | Imperial |

|---|---|---|

| Thermal Conductivity | 51.9 W/mK | 360 BTU in/hr.ft².°F |

C20 Forging Properties:

C20 is easy to forge and can be heated to the recommended temperature for forging, generally around 880-910°C.

C20 Stress Relieving:

Stress relieving can be conducted on C20 steel by heating to a moderate temperature after machining to remove internal stresses.

C20 Normalizing:

For normalizing, C20 steel is heated to 880-910°C and allowed to cool in air to refine the grain structure and enhance its machinability.

C20 Annealing:

Annealing is recommended by heating the steel to 880-910°C, followed by slow cooling in the furnace to ensure maximum machinability.

C20 Density:

The density of C20 steel is typically around 7.85 g/cm³, providing a good balance between weight and strength.

C20 Machinability:

C20 steel has good machinability, rated at 65%, making it suitable for turning, milling, and drilling operations. Proper lubrication and moderate cutting speeds enhance surface finish and machinability.

C20 Welding:

C20 can be welded easily using conventional methods. Preheating is typically not required for thin sections, but thicker sections may benefit from preheating to avoid cracking.