Description

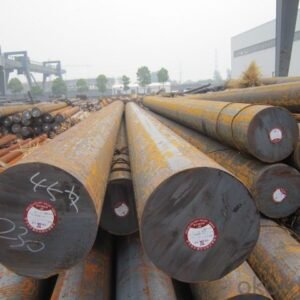

EN19 – Bright Bar Overview:

EN19 steel bright round bar, also known as AISI 4140 round bar, is a high tensile alloy steel containing 1% chromium and molybdenum. It is commonly supplied in hardened and tempered conditions, achieving a tensile strength of 850–1000 MPa (Condition T). It is widely used for its excellent combination of ductility, toughness, wear resistance, and machinability. EN19 is commonly used in the automotive, oil and gas, and engineering sectors for applications requiring strength and high fatigue resistance.

Applications of EN19 Bright Bar:

- Axles and drive shafts

- Crankshafts and connecting rods

- High tensile bolts and studs

- Gears, pinions, and shafts

- Spindles and propeller shaft joints

- Rifle barrels

- Oil and gas industry components (such as hollow bars)

Equivalent Grades of EN19 Bright Bar:

- BS: 709M40

- DIN: 42CrMo2

- IS: 40Cr4Mo3

- EN: EN19

- SAE/AISI: 4140

Commonly Supplied Grades Along with EN19: EN1A, EN3B, EN8, EN24, EN31, EN36C, 42CrMo4, SAE4140, 20MnCr5, C45, and others.

Chemical Composition of EN19 Bright Bar:

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.35–0.45 |

| Silicon (Si) | 0.15–0.30 |

| Manganese (Mn) | 0.50–0.80 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.040 |

| Chromium (Cr) | 0.90–1.50 |

| Molybdenum (Mo) | 0.20–0.40 |

| Iron (Fe) | Balance (96.78–97.77) |

Mechanical Properties of EN19 Bright Bar:

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 655 MPa | 95,000 psi |

| Yield Strength | 415 MPa | 60,200 psi |

| Bulk Modulus | 140 GPa | 20,300 ksi |

| Shear Modulus | 80 GPa | 11,600 ksi |

| Elastic Modulus | 190–210 GPa | 27,557–30,458 ksi |

| Poisson’s Ratio | 0.27–0.30 | 0.27–0.30 |

| Elongation at Break | 25.7% | 25.7% |

| Hardness (Brinell) | 197 HB | 197 HB |

Heat Treatment of EN19 Bright Bar:

- Normalizing: Heat to 870–900°C, followed by air cooling.

- Hardening: Oil quench from 845°C.

- Tempering: Can be tempered between 205–649°C depending on desired hardness. A tensile strength of 225 ksi can be achieved by tempering at 316°C, and 130 ksi at 538°C.

- Annealing: Anneal at 85°C and cool steadily.

- Stress Relieving: Annealed condition: 600–650°C; Hardened condition: 500–550°C.

Physical Properties of EN19 Bright Bar:

| Property | Metric | Imperial |

|---|---|---|

| Density | 8.08 g/cm³ | 0.292 lb/in³ |

| Melting Point | 1425°C | 2600°F |

Thermal Properties of EN19 Bright Bar:

| Temp. Range (°C) | Coefficient of Thermal Expansion (μm/m.K) | Electrical Resistivity (μΩ.m) | Thermal Conductivity (W/m.K) |

|---|---|---|---|

| 20–100 | 12.2 | 0.263 | 42.6 |

| 20–200 | 12.6 | 0.326 | 42.2 |

| 20–400 | 13.7 | 0.4575 | 37.7 |

| 20–600 | 14.6 | 0.646 | 33.0 |

Forging Properties of EN19 Bright Bar: Forge at a temperature range of 125°C–90°C.

Welding and Machinability of EN19 Bright Bar: EN19 bright bar can be welded using conventional techniques but requires post-weld heat treatment to restore its mechanical properties. The steel has good machinability when in the annealed condition.

Hardness of EN19 Bright Bar:

- Brinell Hardness: 197 HB

- Oil Quenched & Tempered Hardness: 28-34 HRC

- Annealed Hardness: Less than 250 HB