Description

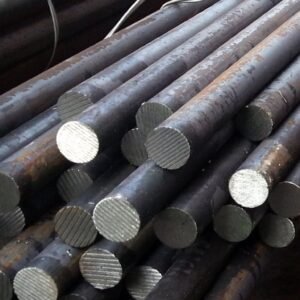

16MNCR5 – BRIGHT BAR Grade Overview

16MnCr5 steel is an alloyed case-hardening engineering steel designed for components requiring a core tensile strength between 800 – 1100 N/mm² and excellent wear resistance. This steel grade is widely used in the manufacturing of critical vehicle and mechanical engineering parts such as piston bolts, camshafts, and levers.

Applications of 16MNCR5 – BRIGHT BAR:

- Piston Bolts

- Camshafts

- Levers

- Mechanical Engineering Components

Equivalent Grades for 16MNCR5 – BRIGHT BAR:

- ASTM: A29/A29M

- DIN: EN 10083/3

- JIS: G4053

- DIN/T: DIN17210

Additional Grades:

MS, EN1A, EN3B, EN8, EN8D, EN9, EN24, EN31, EN32B, EN36C, EN41B, EN43B, EN47, EN353, IS2062, 42Crmo4, HCHCR, D2, D3, H-11, H-13, CW-1, OHNS M2, M35, M42, DIN-1.2714, P20, P20+S, P20+Ni, SCM420, ASTM SA-36, ASTM SA-105, SAE1018, SAE1010, SAE4140, SAE8620, 20MNCR5, C20, C45, C50, C60, CK45, 20C8, 40C8, 45C8, 55C8, C55MN75, SAE52100, S40C, S355J2G3.

Supply Range and Pricing:

For information on our supply range and pricing, please contact us directly.

16MNCR5 – BRIGHT BAR Chemical Composition:

- Carbon (C): 0.14 – 0.19%

- Silicon (Si): ≤ 0.40%

- Manganese (Mn): 1.00 – 1.30%

- Phosphorus (P): ≤ 0.035%

- Sulfur (S): ≤ 0.035%

- Chromium (Cr): 0.80 – 1.10%

Mechanical Properties of 16MNCR5 – BRIGHT BAR:

- Hardness: Details available based on specific heat treatments.

- Heat Treatment: Customized heat treatment processes available upon request.

- Hardening: Specific hardening procedures provided upon inquiry.

- Tempering: Guidelines available based on application requirements.

- Physical Properties: Detailed specifications provided as needed.

- Thermal Properties: Information on thermal conductivity and expansion available on request.

- Forging Properties: Forging details provided on inquiry.

- Stress Relieving: Stress relieving methods and recommendations available.

- Normalizing: Normalizing processes and specifications provided.

- Annealing: Annealing details available for various conditions.

- Density: Standard density information provided.

- Machinability: Good machinability; specific details available upon request.

- Welding: Welding guidelines and procedures available.

Supply Cities:

Mumbai Ahmedabad, Amaravathi, Ambattur, Bangalore, Belgaum, Chennai, Chittoor, Coimbatore, Dindigul, Mysore, Nellore, Hyderabad, Kochi, Mangalore, Tirupur, Tuticorin, Madurai, Andhra Pradesh, Karnataka, Puducherry, Kerala, Tamil Nadu, Telangana, Visakhapatnam, Kochi, Kerala, Hubli-Dharwad, Karnataka, Ghaziabad, Kolkata.

People also search as:

16MNCR5 Bright Bars, 16MNCR5 Bright Bar Manufacturers, 16MNCR5 Bright Bar Suppliers, 16MNCR5 Bright Bar Stockist, 16MNCR5 Bright Bar Dealers, 16MNCR5 Bright Bar Distributors, 16MNCR5 Bright Bar Wholesalers, 16MNCR5 Bright Bar Steel Traders, 16MNCR5 Steel Bright Bar Hexagon Distributors, 16MNCR5 Steel Bright Round Bar, 16MNCR5 Steel Bright Bar Companies Near me.

16MnCr5, 16MnCr5 Bright Bar, 16MnCr5 Bright Bar Chemical composition, 16MnCr5 Bright Bar Mechanical properties, 16MnCr5 Bright Bar Equivalent Grades, 16MnCr5 Steel Bright Hexagon Bar, 16MnCr5 Bright Bar Manufactures, 16MnCr5 Bright Bar Suppliers, 16MnCr5 Bright Bar Dealers, 16MnCr5 Bright Bar Stockist, 16MnCr5 Bright Bar Distributors, 16MnCr5 Bright Bar Wholesalers, 16MnCr5 Bright Bar Traders.