Description

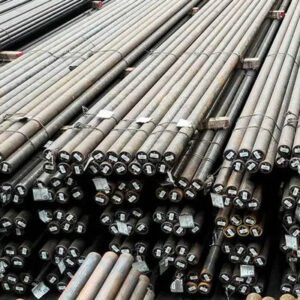

AISI 1070 Carbon Steel Product Description

Overview

AISI 1070 carbon steel is the material of choice for professionals seeking strength and versatility for industrial and manufacturing applications. Renowned for its exceptional durability and flexibility, this steel grade stands out in demanding environments. Whether you’re crafting resilient springs, sharp blades, or secure fasteners, AISI 1070 delivers reliability you can count on.

Key Features

- High Tensile Strength: Built to endure, AISI 1070 resists deformation under heavy loads.

- Moderate Hardenability: Easily achieves hardness through heat treatment, balancing durability with workability.

- Exceptional Wear Resistance: Designed to withstand impact and friction in rigorous applications.

- Machinable Composition: Processes smoothly, reducing fabrication time and cost.

Applications

AISI 1070 is ideal for products that require both strength and precision. Typical uses include:

- Springs used in heavy machinery

- Blades crafted for industrial cutting tools

- Fasteners intended for high-stress environments

Benefits

Choosing AISI 1070 means opting for a material that combines cost-efficiency with superior performance. Its durability ensures longevity, minimizing the need for replacement and lowering your overall operational costs. Additionally, its response to heat treatments and machinability allow manufacturers to optimize production without compromising on quality.

Technical Specs

- Carbon Content: Approximately 0.67% to 0.75%

- Hardness (Annealed): Approx. 190 Brinell

- Machinability: Rated at roughly 55% compared to B1112 steel

- Heat Treatment Compatibility: Excellent for processes such as quenching and tempering

With AISI 1070 carbon steel, you’re not just investing in a material; you’re investing in unmatched performance and reliability.